The technique behind Yakisugi

Discover the ancient Japanese technique where wood is transformed by fire. A craftsmanship process that unites beauty, durability and natural protection. Yakisugi, also known as Shou Sugi Ban, is more than a finish - it's a philosophy.

What is Yakisugi?

Yakisugi, literally translated as "burnt cedar wood", is a traditional Japanese wood processing technique that originated more than 300 years ago in the Japanese Chugoku region. The technique is also called **Shou Sugi Ban** (焼杉板), which means "burnt cedar plank".

Originally developed as a natural way to protect wooden facades against the elements, this technique has proven to be one of the most durable and aesthetically appealing wood processing methods in the world. In Japan, there are examples of Yakisugi facades that have lasted for more than 100 years without significant deterioration.

At Yakisugi Atelier, we combine this centuries-old tradition with modern techniques and quality control. We respect the artisanal character of the process, but use contemporary methods for consistent quality and efficiency. Every piece of wood is inspected and approved before it leaves our atelier.

The production process

From raw plank to protected end product: every piece of Yakisugi goes through a careful process of transformation. Every step is crucial for the final result.

Selection & Preparation

We select only FSC certified Cryptomeria japonica wood. This Japanese cedar is ideal due to its straight grain, natural oils and stable structure. The wood is dried to the optimal moisture content of 12-15%.

Controlled Burning

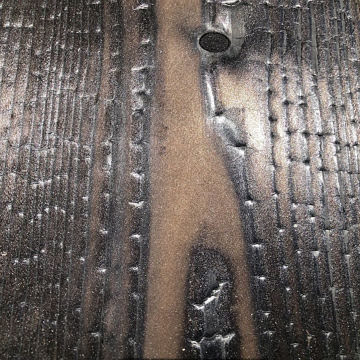

The wood is burned in a controlled manner to the perfect depth of 3-7mm. This creates the characteristic crackled texture and a protective carbon layer. Temperature and burning duration are carefully controlled for consistent quality.

Cooling & Extinguishing

After burning, the wood is extinguished in a controlled manner with water. This stops the combustion process at the right moment and strengthens the structure. The cooling speed influences the final texture and color.

Brushing & Finishing

The burnt wood is brushed to remove loose carbon particles and achieve the desired texture. Optionally, a protective oil is applied that deepens the color and provides extra protection against UV radiation.

Traditional with modern precision

Although we respect traditional Japanese methods, we use modern techniques for consistent quality and efficiency. Every plank is checked for depth of the burnt layer, texture and color consistency. Only planks that meet our strict quality standards leave our atelier.

Why choose Yakisugi?

The burning process gives Yakisugi unique properties that conventionally treated wood does not have. Burnt wood is naturally protected and low-maintenance.

Natural protection against rot

The burnt layer acts as a natural shield against moisture, rot and mold. The carbon layer is hydrophobic and prevents water from penetrating the wood. No chemical treatment needed - the protection comes from the burning process itself.

Insect repellent without chemicals

Insects such as woodworm and longhorn beetles naturally avoid the burnt wood. The carbon layer is not edible for them and the natural oils in Cryptomeria japonica are repellent. This makes Yakisugi ideal for outdoor applications.

UV-resistant and color-fast

The dark carbon layer absorbs UV radiation and protects the underlying wood against weathering and discoloration. Yakisugi ages with grace and develops a beautiful silver sheen without graying like untreated wood.

Fire retardant (class B-s2, d0)

Paradoxically, burnt wood is less flammable than untreated wood. The carbon layer significantly slows down fire spread. Yakisugi has fire class B-s2, d0 certification for use in construction projects.

Water-repellent and fast-drying

The texture and structure of Yakisugi ensure natural water drainage. Water beads off and the wood dries quickly, which prevents mold formation. The crackled texture increases the surface area for faster evaporation.

Long lifespan (50+ years)

Yakisugi has a proven lifespan of more than 50 years without significant deterioration. In Japan, there are examples of Yakisugi facades that have lasted for more than 100 years. This makes it a sustainable investment.

Yakisugi vs alternatives

How does Yakisugi compare to other facade cladding and wood finishes?

| Property | Yakisugi | Thermowood | Impregnated wood | Untreated wood |

|---|---|---|---|---|

| Lifespan | 50+ years | 25-30 years | 15-20 years | 5-10 years |

| Maintenance | Minimal | Regular | Annual | Intensive |

| Chemical treatment | None | None | Yes | None |

| Fire class | B-s2, d0 | D-s2, d0 | D-s2, d0 | D-s2, d0 |

| Aesthetics | Unique, timeless | Natural | Green/brown | Grays |

| Sustainability | FSC, water-saving | FSC possible | Chemical | FSC possible |

Different finishes

By varying the burning depth, brushing intensity and post-treatment, we create different finishes with unique characters. From deep black with coarse texture to subtle matte with fine structure.

Eurosugi Porto

Deep crackled texture with silver sheen. The most dramatic finish with coarse texture and deep black.

Eurosugi Amsterdam

Medium texture with matte black. Balance between texture and smoothness, suitable for modern architecture.

Eurosugi Luxembourg

Fine texture with deep black. Elegant and refined, perfect for interior applications.

Eurosugi Rome

Structured with black-brown tones. Warm appearance with visible wood grain.

Eurosugi Natural

Natural wood color with light burning. Warm appearance with subtle protection, ideal for natural aesthetics.

Custom

Custom-made finish according to your specifications. We can adjust the burning depth, texture and post-treatment to your wishes.

Sustainability & certifications

Yakisugi is not only sustainable in use, but also in production. We work according to strict sustainability standards.

FSC Certification

All our wood comes from FSC certified suppliers. This guarantees sustainable forest management where new trees are planted for every tree felled.

Clean Water Certificate

Our production process is certified for water-saving work. We use minimal amounts of water and purify all wastewater.

Green Deal Partner

As a Green Deal partner, we commit to further sustainability of our production and promoting sustainable construction.